I’m excited to work with GL Veneer. With more than 40 years in the wood business, these guys know about wood. I hope you will visit and subscribe to their channel and get the inside story of some of the amazing logs they’ve come across over the years.

This is the veneer product that I’m using on the upcoming chest of drawers project, so I wanted to make a quick “Working with Veneer 101” video to get everyone up to speed. In the video, I talk about how I’ve been using veneer for 25 years without any problems.

How To Work With Wood Veneer

When building a cabinet, you’re really just building a box. By building a box with plywood, you don’t have to worry about expansion or contraction like with a solid wood. This gives you more freedom with design, trim and finishing products.

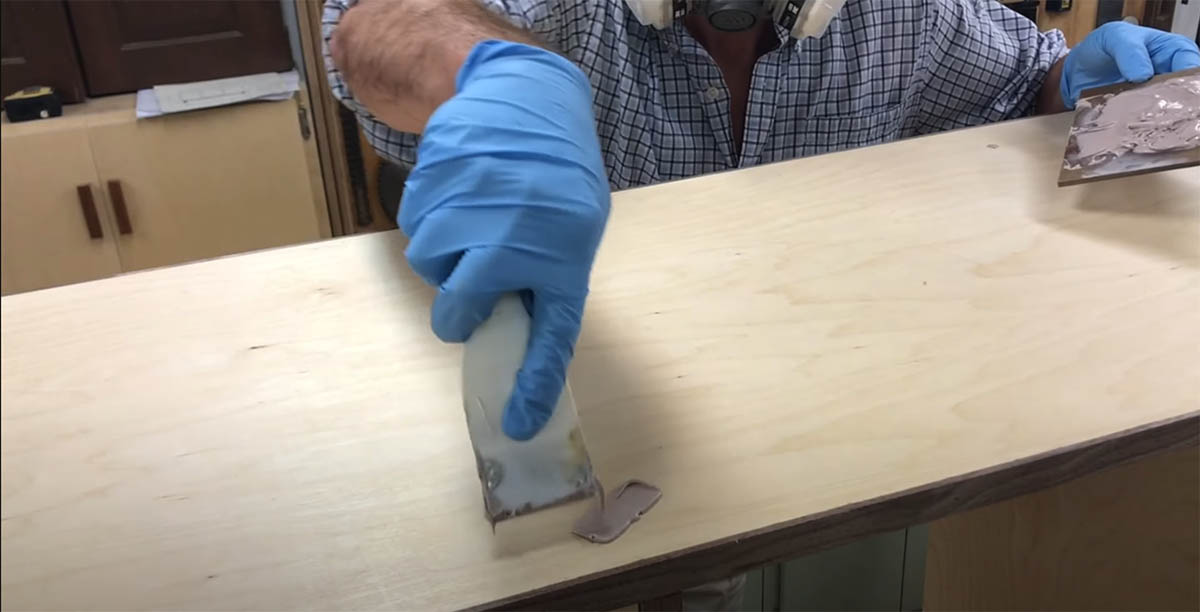

A good trick when working with veneer is to fill any imperfections in the surface before covering. Imperfections will telegraph through the veneer, so inspect your surfaces carefully and fill any pits with auto-body Bond-O. This 2-part system is easy to use and dries quickly but make sure you sand it really well after it dries.

Prepping for Wood Veneer

When you’re ready cut your veneer to size, cut it about 1/2″ heavy to allow for a 1/4″ overhang on all sides. When applying the veneer, consider the order in which you apply the sheets. Lay your panels in order from the least visible panel to the most visible panel. Start with the back (if you’re covering the back), then the sides, then the top. Use contact cement and a J-Roller to place and secure the veneer and use a flush-cut router bit to trim the veneer. Finish the edges with light sandpaper but since veneer is very thin, DO NOT go crazy with the sandpaper. Just sand enough to knock the nibs off and clean up the edge with 320 grit sandpaper.

Wood Veneer For Beginners

Working with veneer can be a little tricky but if you go through the process, it will expand your design and building vocabulary and opens up a whole new world of design and finish options.

I hope you found this helpful. Thanks for watching and I’ll see you next time!

Sponsored By:

Leading the industry in the most responsible management of the earth’s resources is a role we cherish. GL Veneer has become one of the most trusted eco-conscious, responsibly-sourced and reclaimed wood suppliers in Los Angeles, the West Coast, and the world. But more than production or profit, we gauge success on our ability to maximize the proliferation of our forests, then optimizing the yield of every tree.